Best Seller Wave Process Recommendations

Update Time: 23 Oct 2025 04:28

Below are our suggested practices for managing best seller SKUs in waves.

1. When to Use Best Seller Waves

- A single product or a few SKUs receive a large number of orders

- Repeated picking for the same SKU is inefficient

- Used in high-demand scenarios like promotions.

2. Wave Strategy Setting

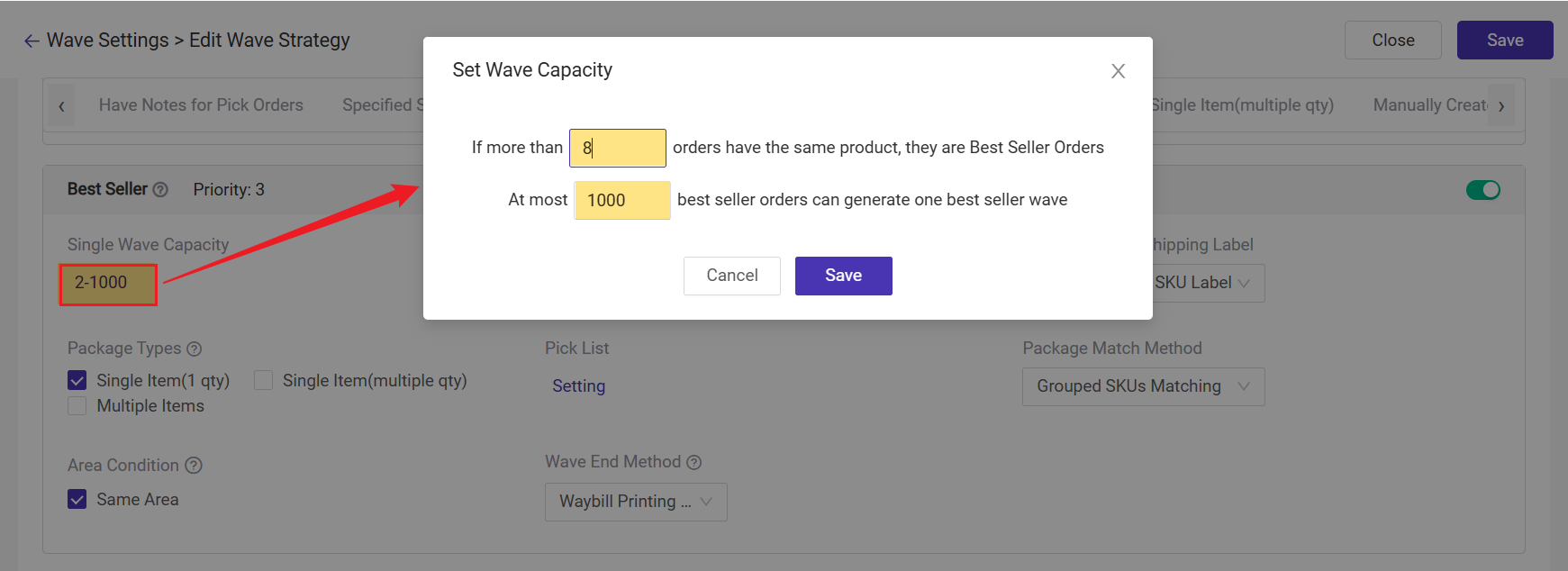

1) Wave Capacity Setting: For Best Seller, you can configure the number of identical orders and the order threshold for creating a Best Seller Wave.

-

For monthly order volume around 12,000–13,000: set to 30–1000

-

For monthly order volume around 1,000–2,000: set to 5–1000

-

For monthly order volume around 5,000: set to 8–1000

-

For higher monthly volumes: consider increasing the minimum value appropriately

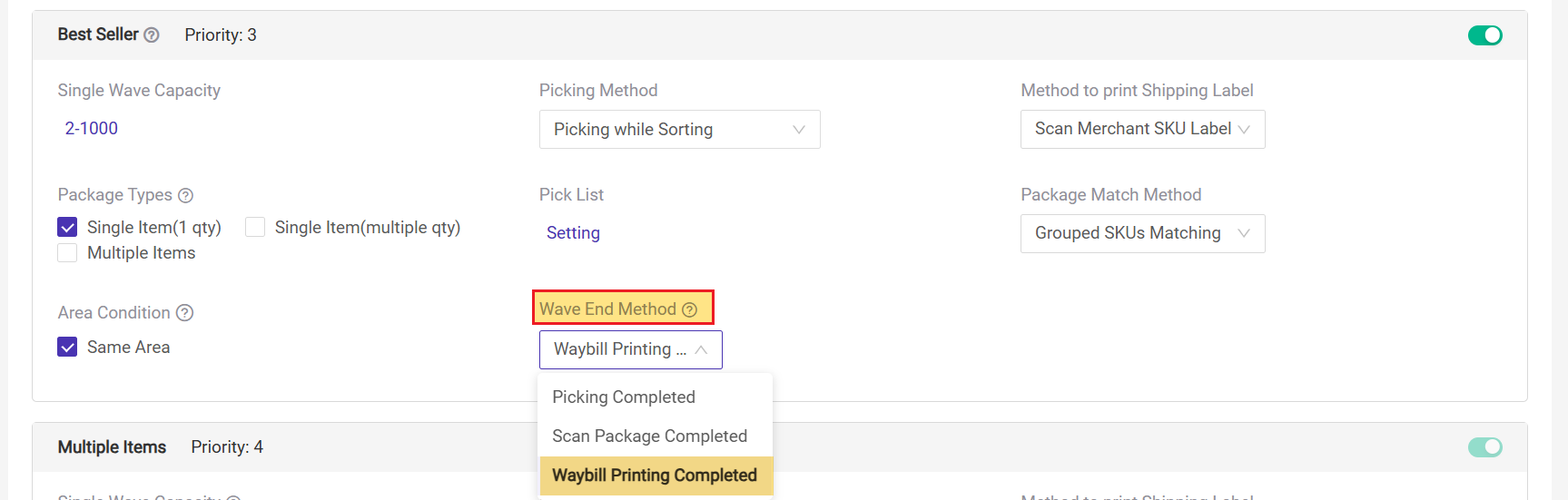

2) Wave End Method: Wave End Method: It is recommended to set it to "When Waybill Printing is Completed".

For wave types like Best Seller, since every package in the wave is identical, it's not necessary to go through the entire process. After generating the wave, you can directly print the shipping labels from the wave list, then use those labels to proceed with picking.

3. Wave Shipment Process

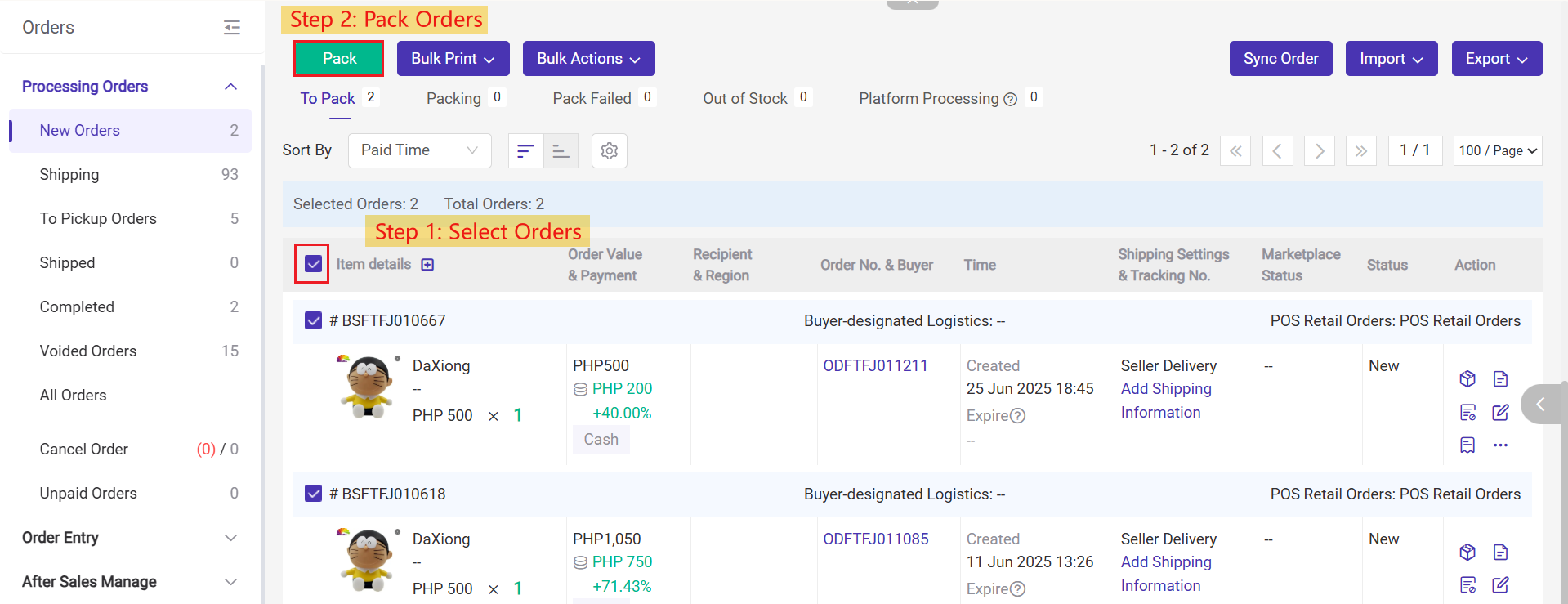

Step 1: Pack Orders on New Orders Page

Before processing orders in waves, go to Order Module > [New Orders], and click Pack. Only after packing the orders will they appear in the Generate Wave page in the WMS module.

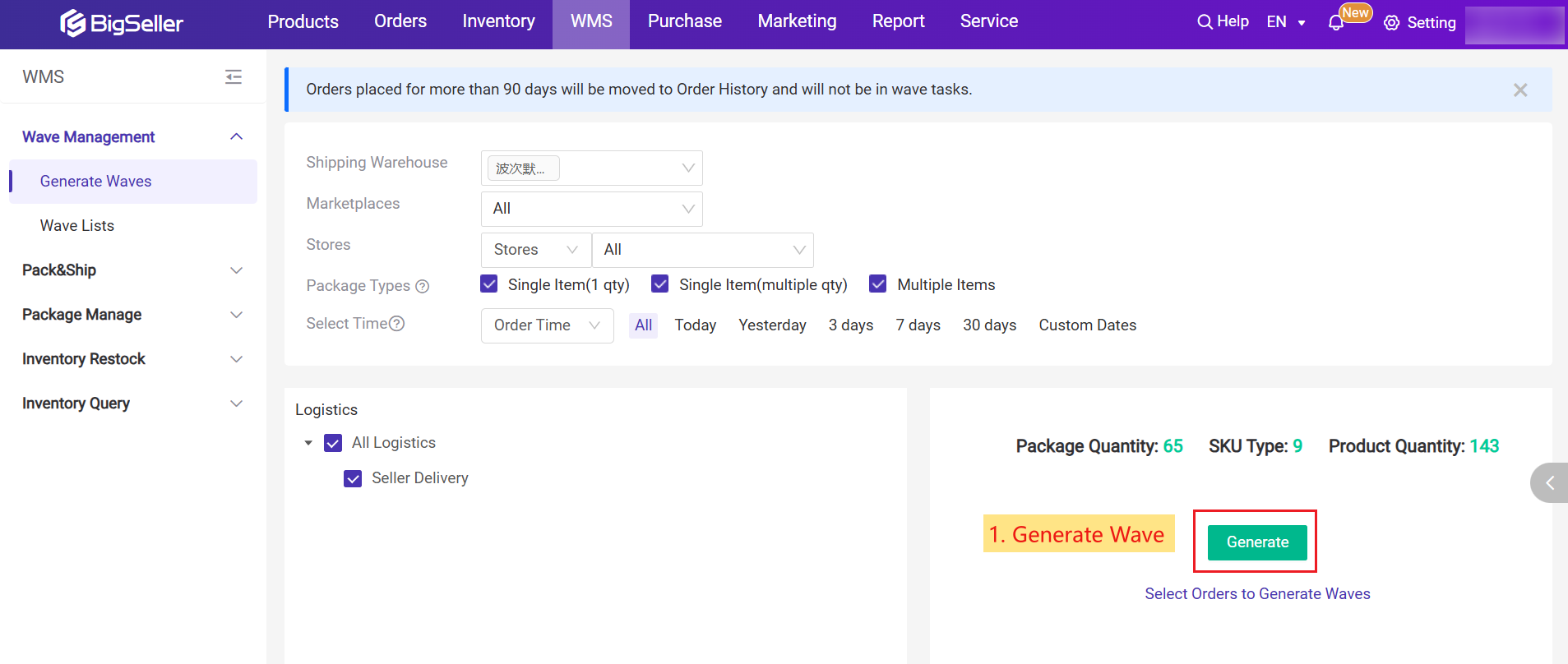

Step 2: Generate Wave

Filter by shipping warehouse, platform, store, order time, shipping method, etc., then click the [Generate] button.

Path: WMS Module > Wave Management > Generate Wave

Step 3: Print Shipping Label

After generating the wave, you can directly print the shipping labels from the wave list, then use those labels to proceed with picking.

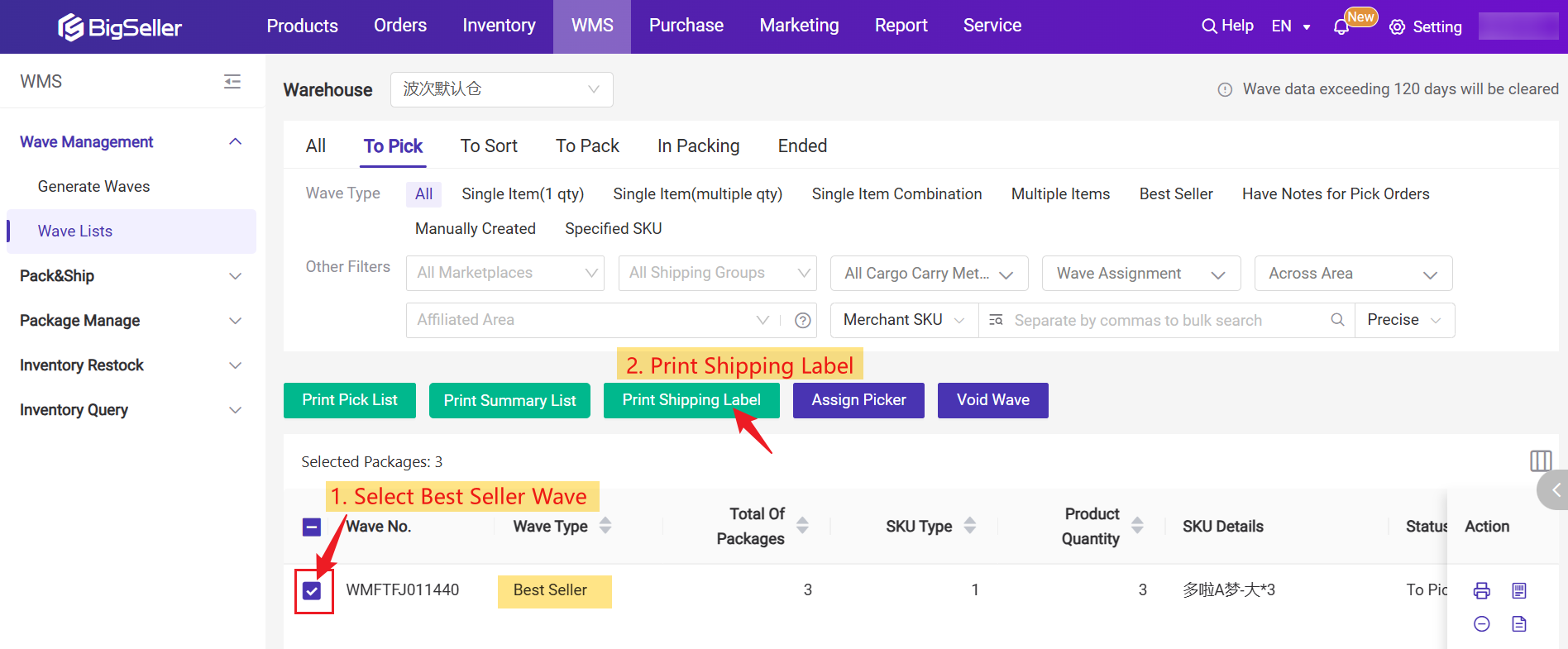

Path: Wave List > To Pick: Select the Best Seller wave and click [Print Shipping Label].

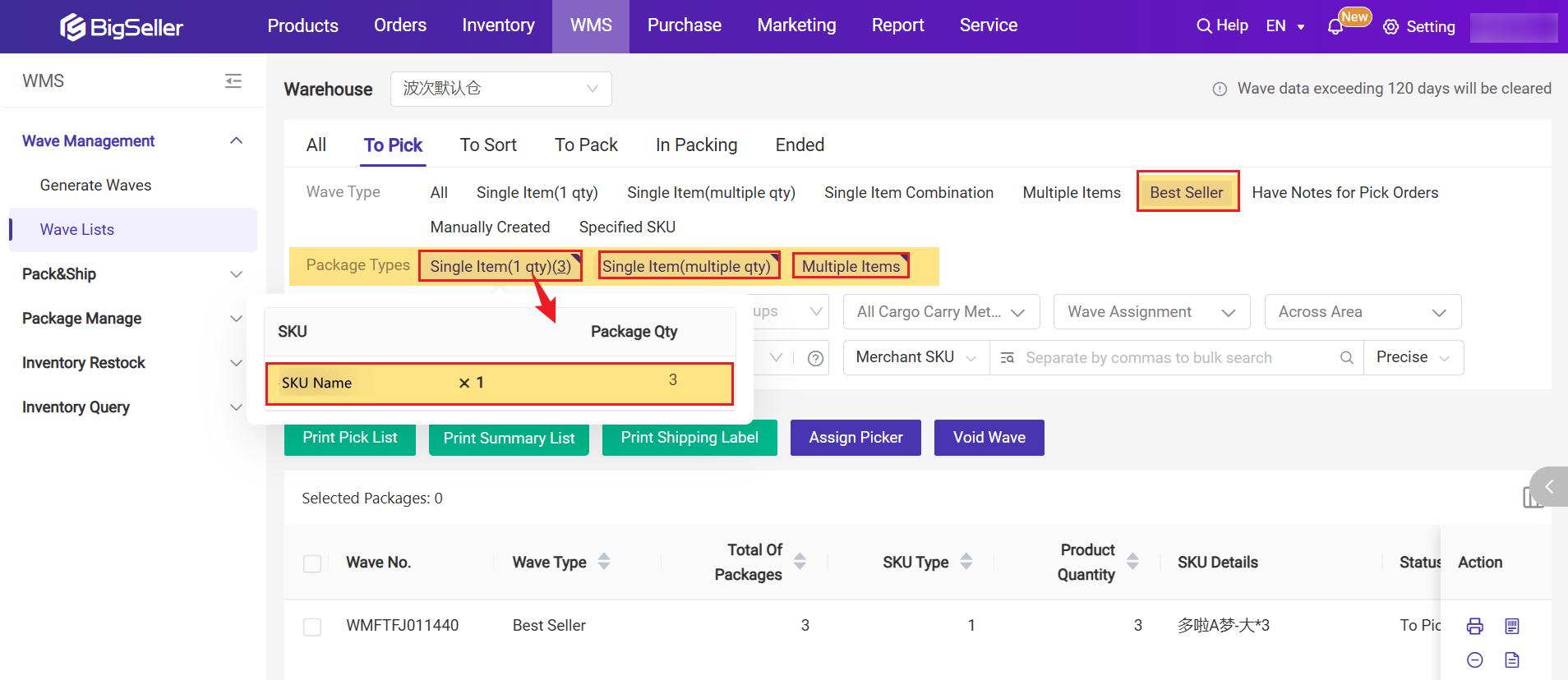

If you first filter best seller waves by Package Type (Single item 1 qty; Single item multiple qty; Multiple items). Package Type supports single or multiple selection.

You can decide the picking order based on package type and order volume — for example, start with simple single-item single-quantity packages before moving on to more complex ones.

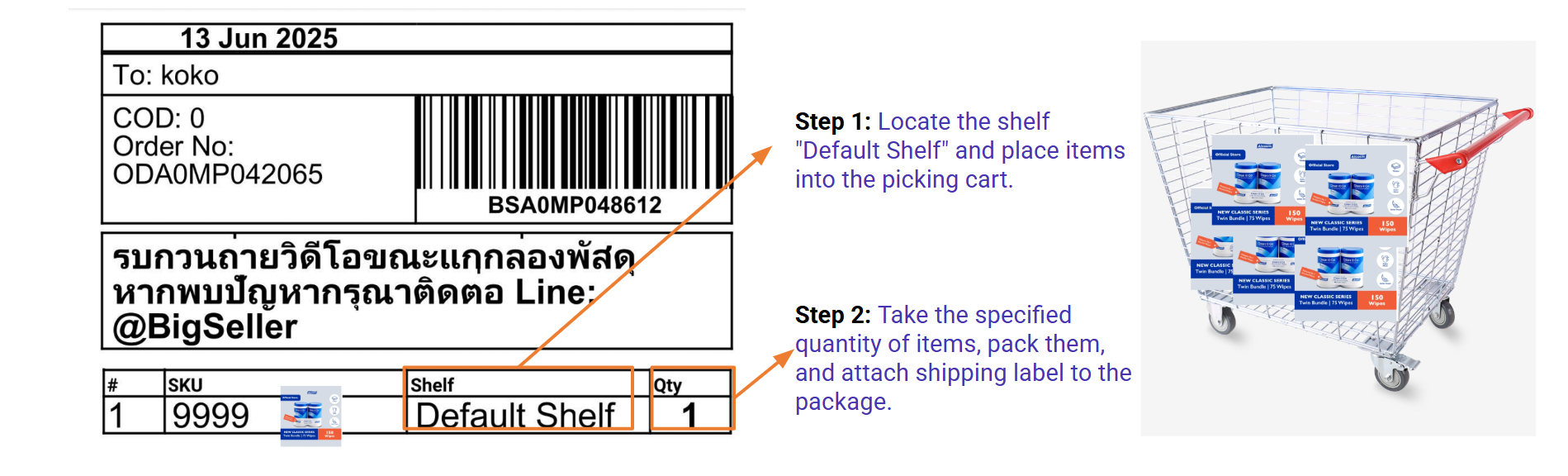

Step 4: Pick and Pack Items according to the Shipping Labels

After printing the shipping labels, warehouse staff pick items in bulk based on the shelf locations shown on the labels. Once picked, the items are passed to the packing team, who sort and pack them according to the fixed quantity per package (e.g., 1 item per parcel for single-item orders) and apply the shipping labels.

Step 5: Ship

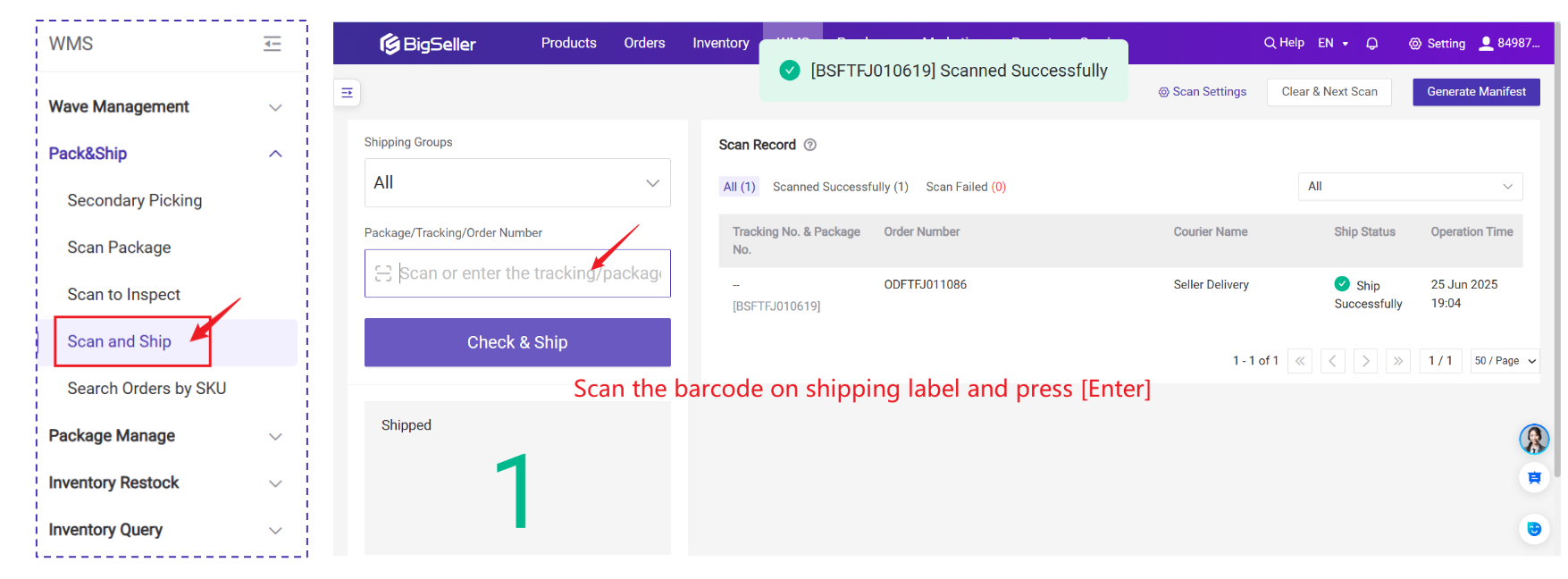

Once the warehouse staff confirm packing is complete, they can use a scanner to ship the order from the Scan to Ship page.

After a successful scan, the order will move to the To Pickup.

Is this content helpful?

Thank you for your feedback. It drives us to provide better service.

Please contact us if the document can't answer your questions