Warehouse Preparation Checklist Before Starting Wave Shipments

Copy link & title

Update Time: 14 Jul 2025 03:48

📌 For detailed steps on wave operations, please refer to the BigSeller Wave Shipment Onboarding Guide to learn about warehouse management and how to use wave shipments.

Before using wave shipments, it's crucial to ensure your warehouse is fully prepared to handle the increased pace and complexity.This article outlines the key steps your team should take to get the warehouse ready for smooth wave shipping operations.1. Equipment to Improve Warehouse Operational Efficiency

2) Printer (Must Have):

3) Barcode Scanner

4) PDA (Personal Digital Assistant):

5) Picking Cart / Sorting Cart

Before using wave shipments, it's crucial to ensure your warehouse is fully prepared to handle the increased pace and complexity.This article outlines the key steps your team should take to get the warehouse ready for smooth wave shipping operations.

1. Equipment to Improve Warehouse Operational Efficiency

1) Computer (Must Have):

The core device for managing warehouse operations. It is used to process orders, manage inventory, and monitor shipments. It helps reduce manual input errors and increases overall work efficiency.

2) Printer (Must Have):

Used to print shipping labels, picking lists, and SKU labels. Ensures that all order and product information is clearly visible, helping to avoid mismatches during picking or shipping.

(You may consider recommending certain brands like Giabo; note that HPRT printers might not be compatible.)

3) Barcode Scanner

A barcode-reading device used to scan product label, order barcodes. It automatically inputs information into the system, improving the accuracy and speed of picking, checking, and shipping.

(Wired scanners are strongly recommended to prevent confusion or misplacement.)

4) PDA (Personal Digital Assistant):

A handheld device that integrates barcode scanning, data collection, and wireless communication. It is used for picking, verification, and inventory counting, making warehouse operations more efficient and accurate while reducing human error.

(A large screen and Android version 5.0 or higher are recommended.)

5) Picking Cart / Sorting Cart

Used to hold items for orders, allowing warehouse staff to pick multiple orders at once, reducing back-and-forth trips and improving picking efficiency.

6) Barcode (Label)

Every product, shelf , picking cart, should be associated with a unique barcode. By scanning barcodes, the system ensures accurate matching during picking, shelving, and stocktaking, significantly reducing errors and improving overall warehouse efficiency.

Every product, shelf , picking cart, should be associated with a unique barcode. By scanning barcodes, the system ensures accurate matching during picking, shelving, and stocktaking, significantly reducing errors and improving overall warehouse efficiency.

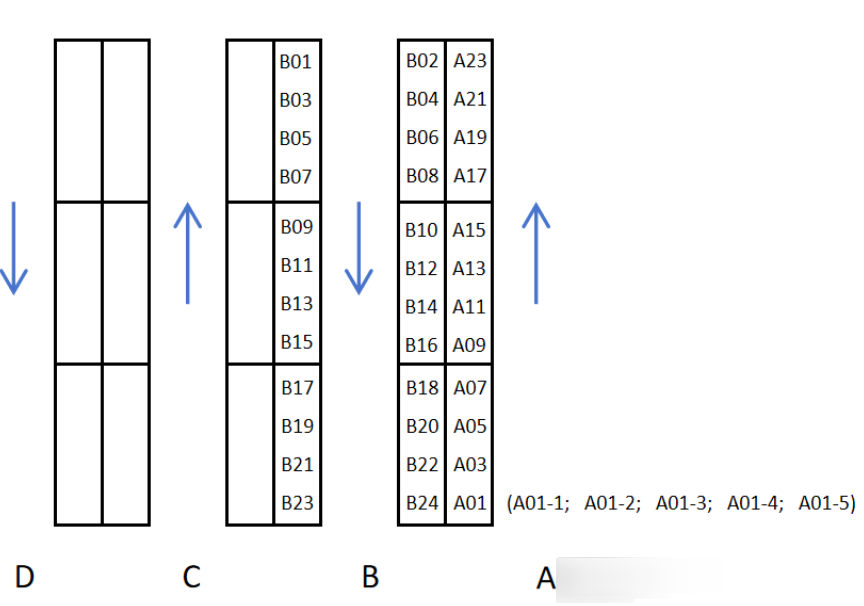

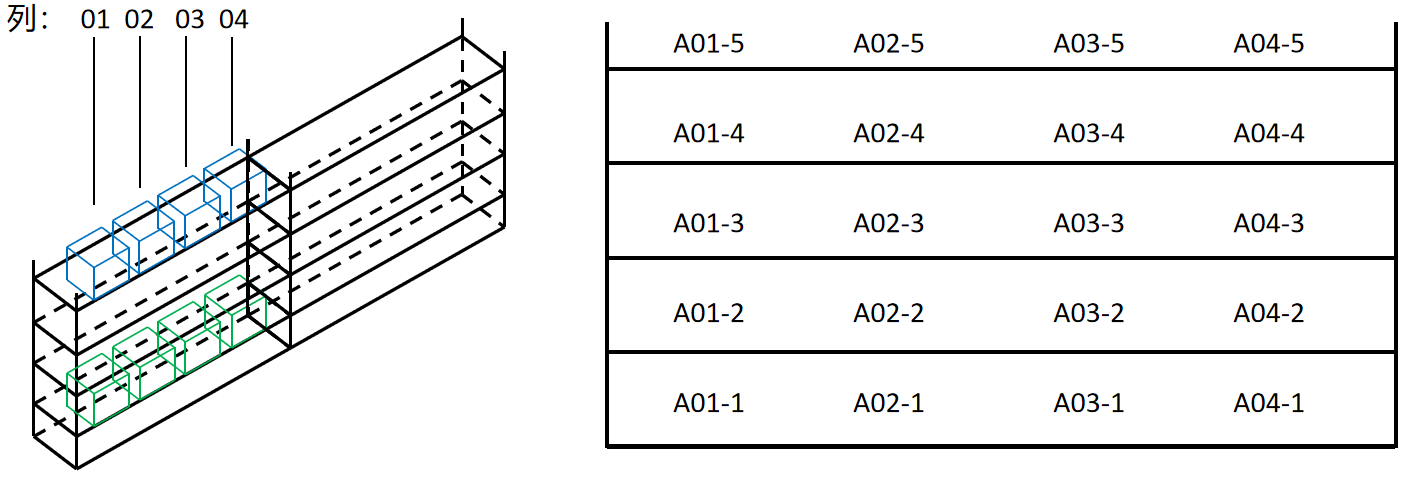

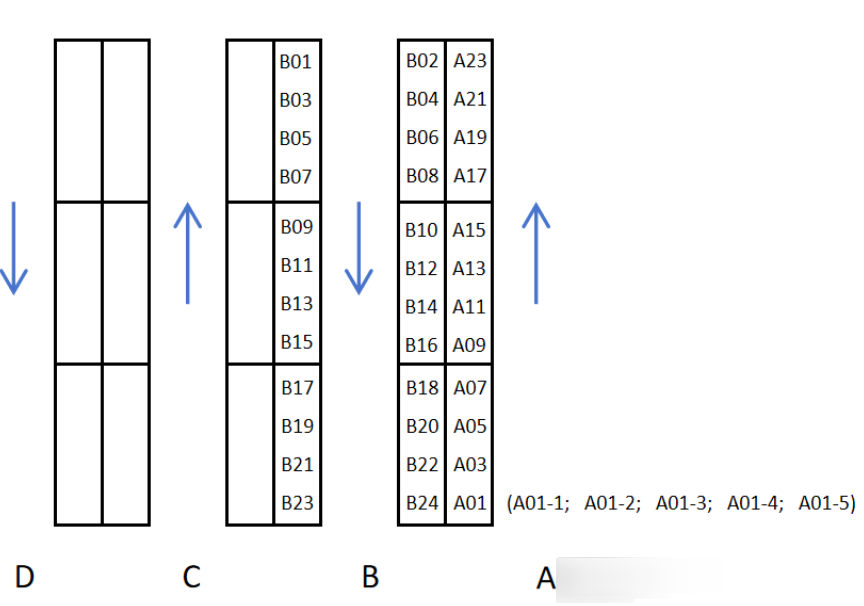

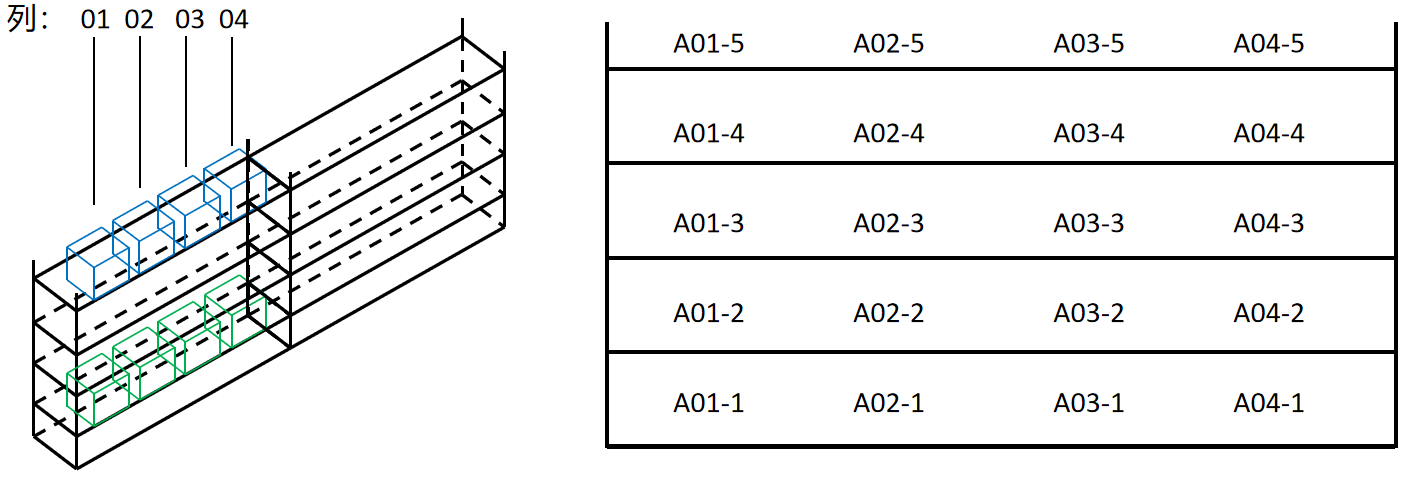

2. Picking shelf Planing and Product Placement

💡 S-Shaped Picking Path (Most common and widely used)

The S-shaped (serpentine) route is suitable for narrow-aisle warehouses where pickers need to pass all racks. The picker enters from one end and moves through each aisle in an “S” pattern, avoiding backtracking and improving efficiency.

Key Points:

-

Each aisle is walked only once.

-

Racks should not be against walls to allow full circulation.

-

Use aisle-based rack naming for easy navigation.

Optimize product arrangement based on quantity, size, and turnover rate to ensure pickers can quickly access items.

Is this content helpful?

Thank you for your feedback. It drives us to provide better service.

Please contact us if the document can't answer your questions

Related Articles