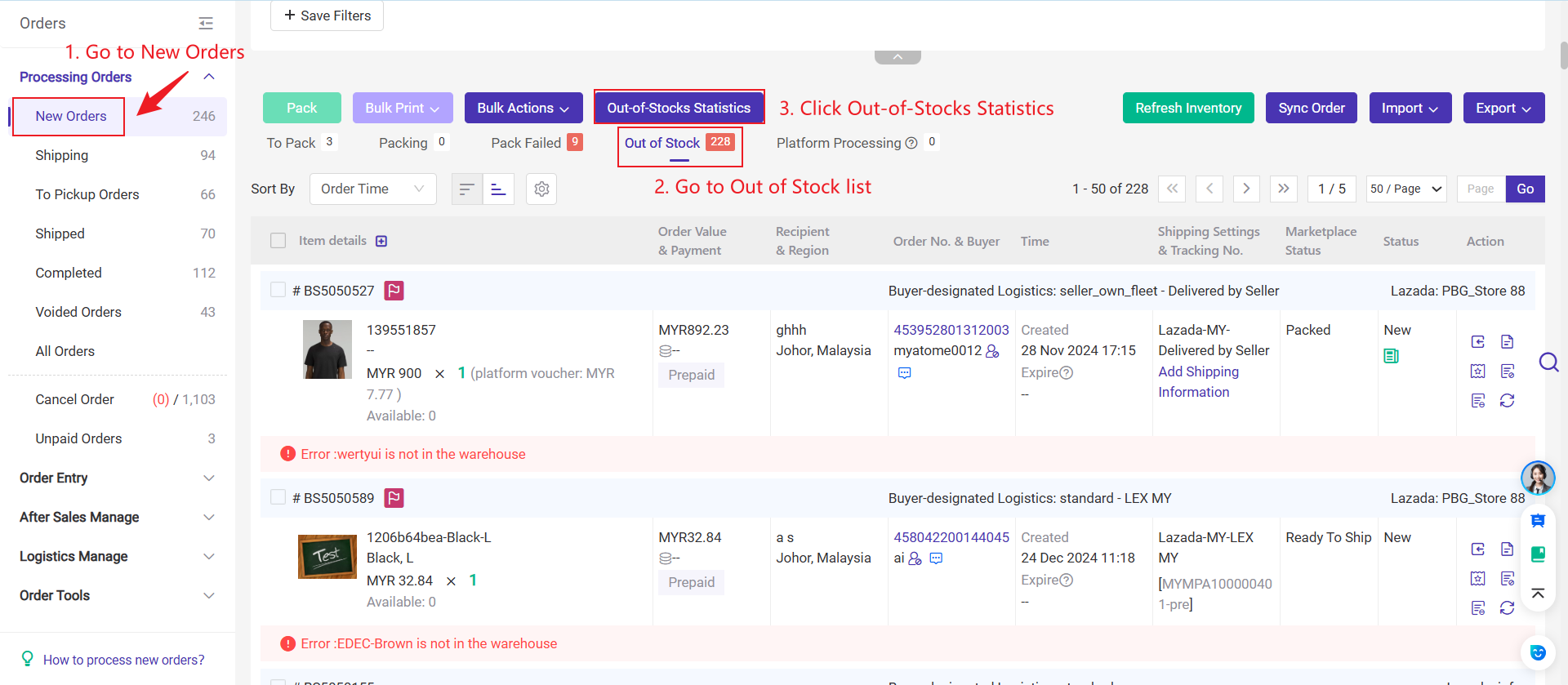

Step1: Go to Orders >New Orders > Out of Stock > Click on Out-of-Stock Statistics.

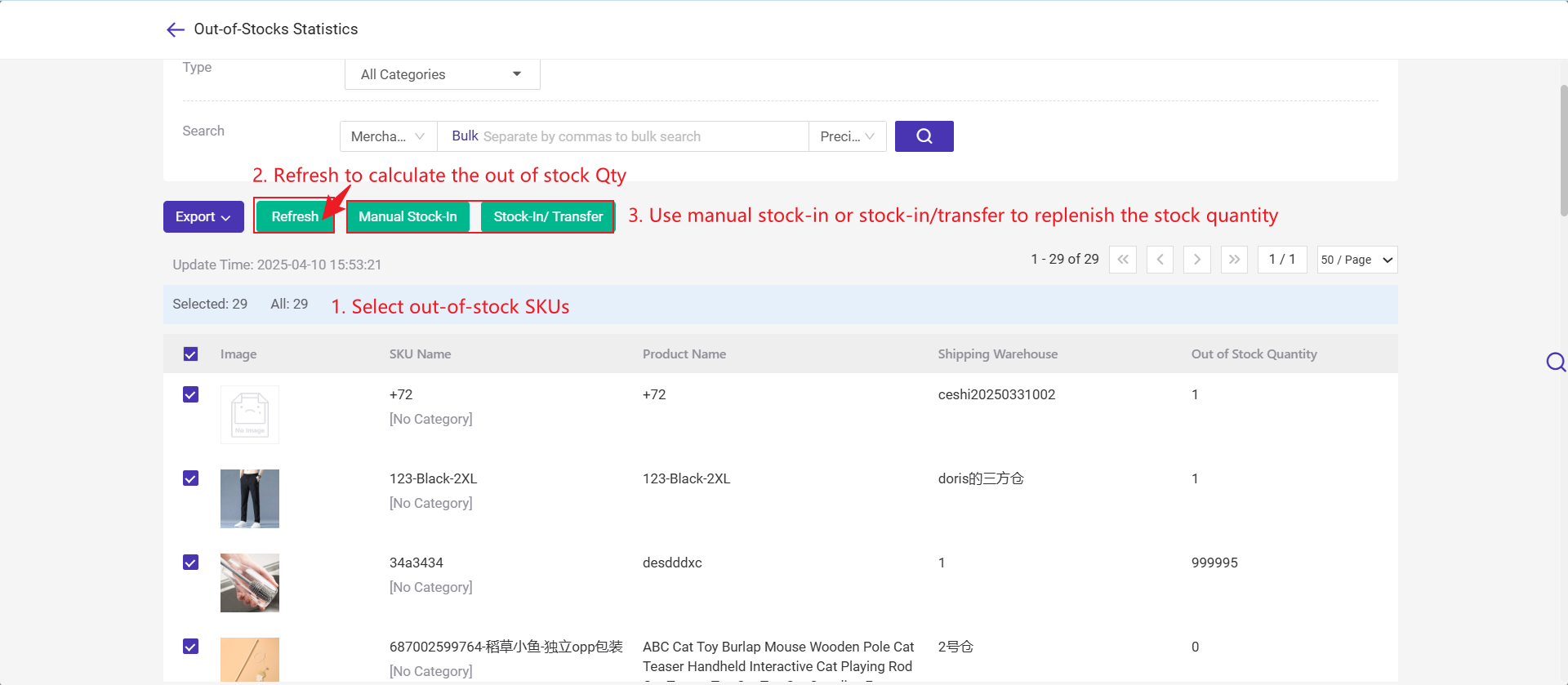

Step 2: Select the out-of stock SKUs (the selected SKUs must be from the same shipping warehouse ) > Click refresh to calculate the out of stock quantity > Click Manual stock-in / transfer button to replenish the stock quantity

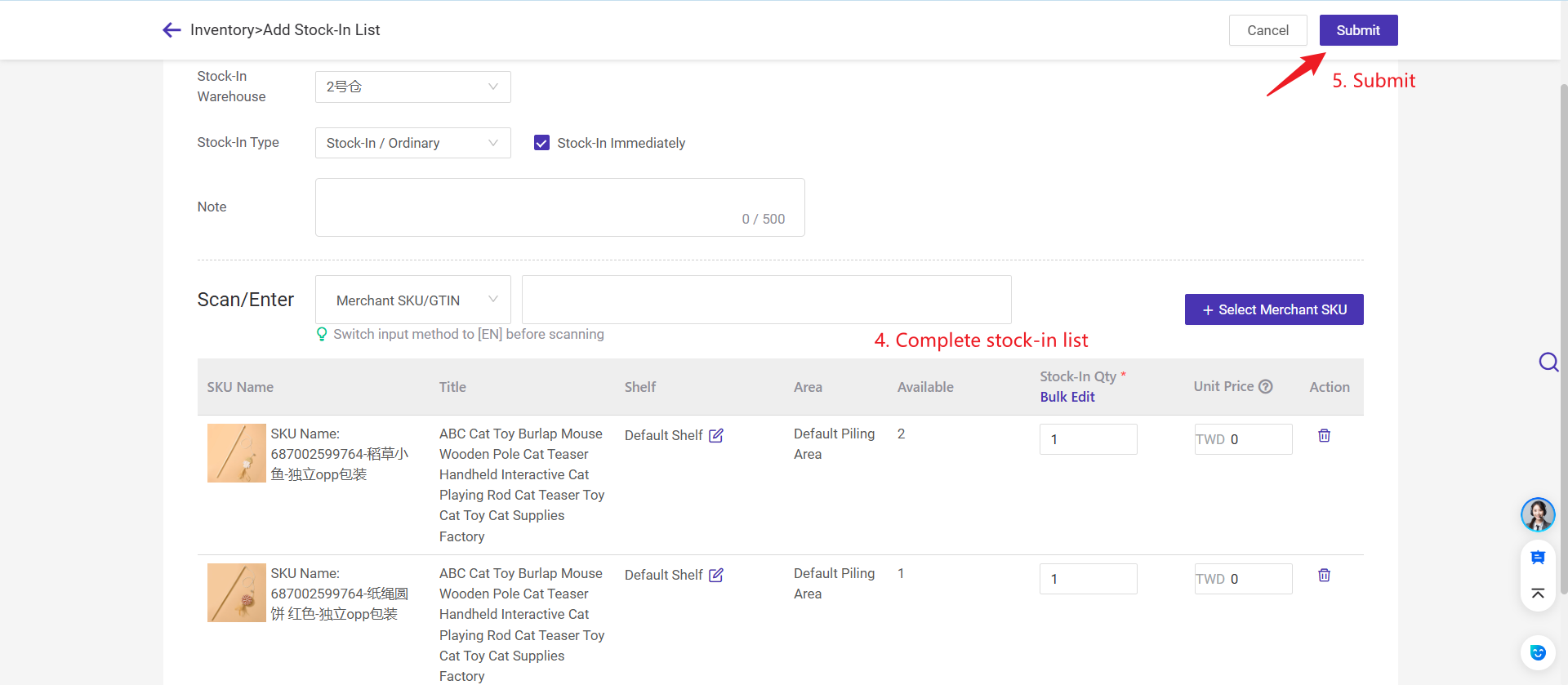

Step 3: Add Stock-in List and Submit

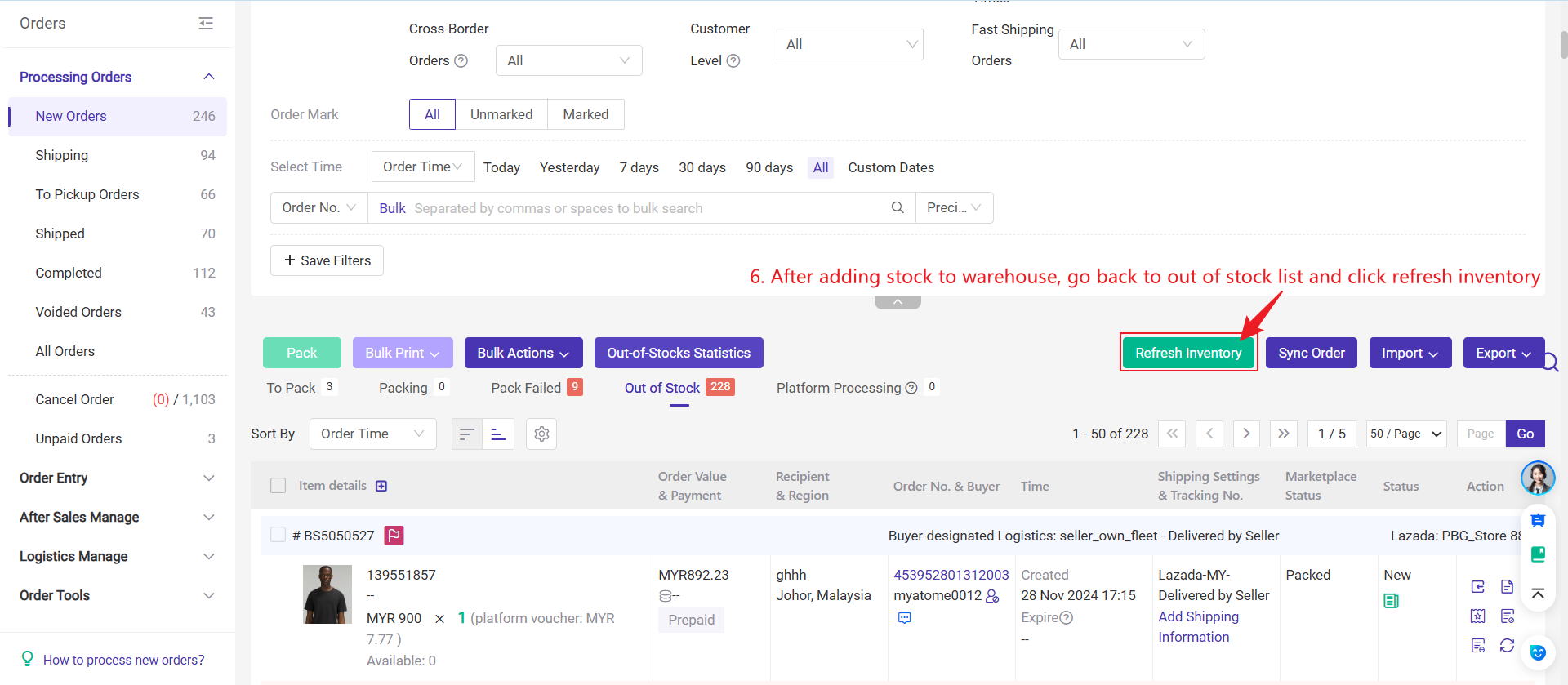

Step 4: Refresh the Inventory

Calculation Formula: Out-of-Stock orders required inventory qty - Out-of-Stock orders allocated inventory qty - available inventory qty

For example: There are three orders, corresponding to Merchant SKU [A], SKU [B] and a combination SKU [A+B] (The combination SKU contains SKU [A]*1 and SKU [B]*1).

| Inventory List | On Hand | Allocated | Available |

| SKU [A] | 20 | 15 | 5 |

| SKU [B] | 0 | 0 | 0 |

Order 1: Purchased [A]*5, allocated [A]*5 -- In Stock

Order 2: Purchased [A+B]*10 -- Out-of-Stock

Order 3: Purchased [A]*10 and [B]*10, allocated [A]*10 and [B]*0 -- Out-of-Stock

Now the calculation is:

[A] Out-of-stocks qty= Out-of-Stock orders required inventory qty(20) - Out-of-Stock orders allocated inventory qty(10) - available inventory qty(5) = 5

[B] Out-of-stocks qty= Out-of-Stock orders required inventory qty(20) - Out-of-Stock orders allocated inventory qty(0) - available inventory qty(0) = 20

💡 Note: Each file can export up to 5000 data, and if there are more than 5000, multiple files will be exported.

How to add the product inventory