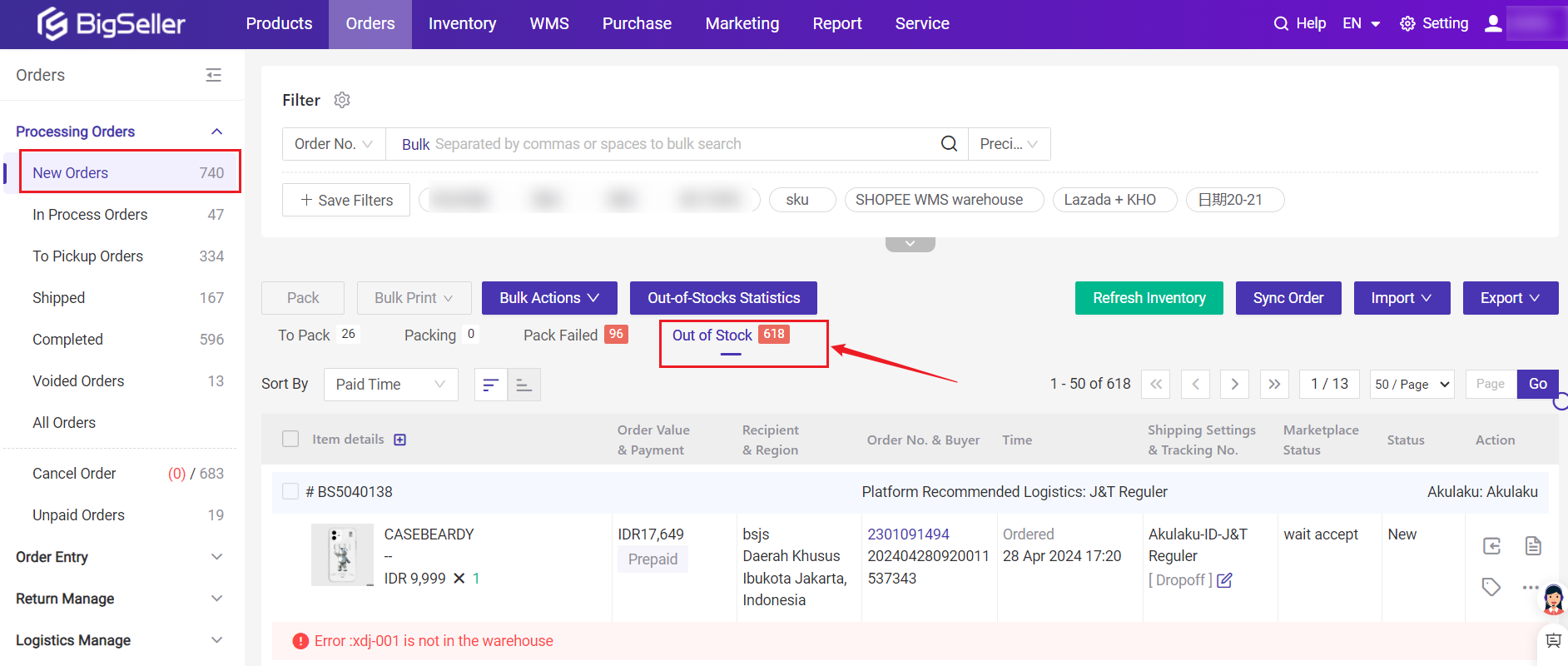

When you process orders in Bigseller, you may find that some of your new orders are under the Out Of Stock tab and you cannot pack those orders.

1. Why is the order on the out-of-stock list?

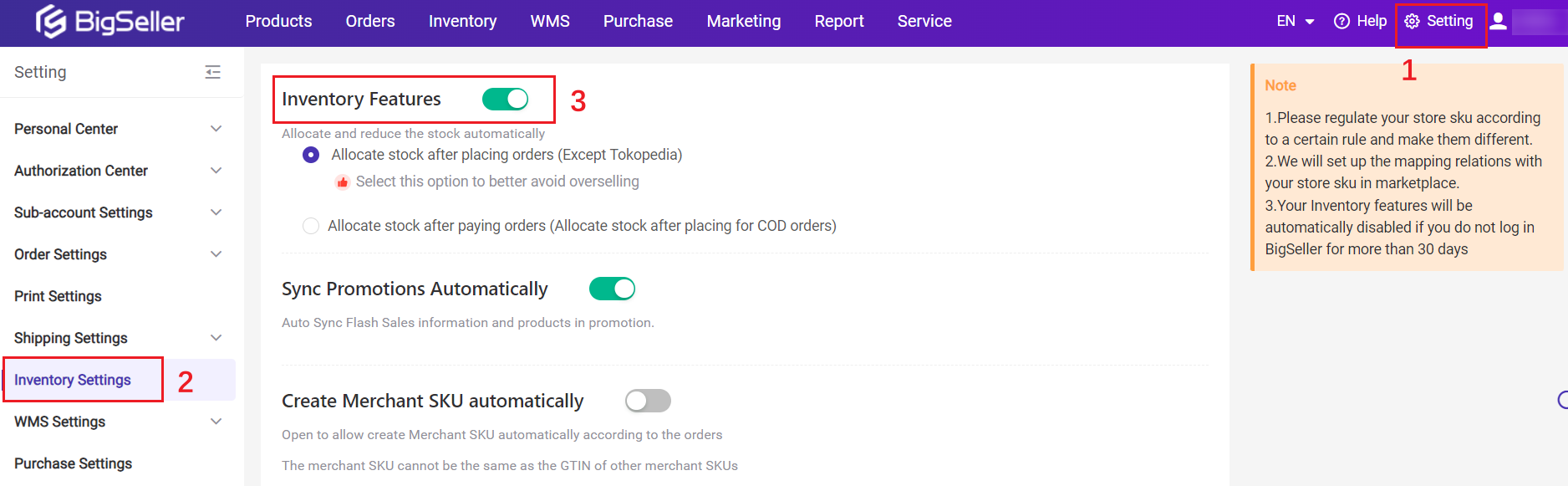

If you have enabled the Inventory Features, Bigseller will allocate stock for your order once a new order syncs to BigSeller. If there are available stocks, this order will be under the To Pack tab after packing, or it will move to the Out Of Stock tab.Three Possible failed reasons:

- The product of this order doesn't have mapping relations with the merchant SKU;

- xxx have no enough stock in the warehouse;

- xxx is not in the warehouse.

2. How to deal with the out-of-stock orders?

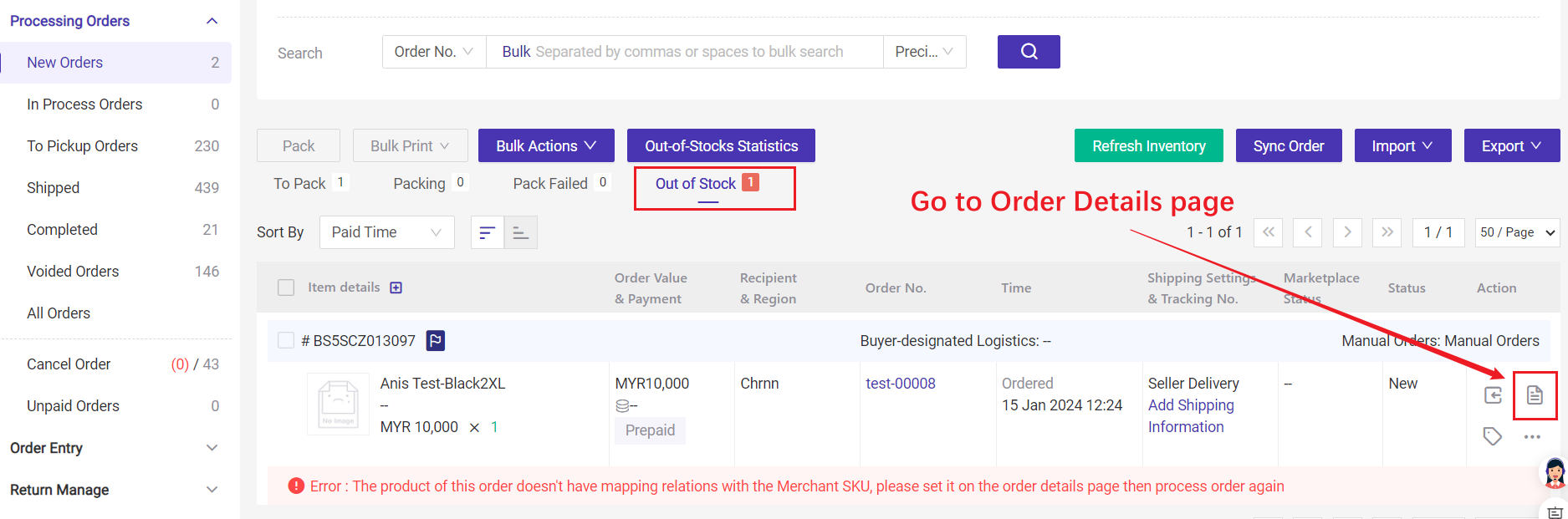

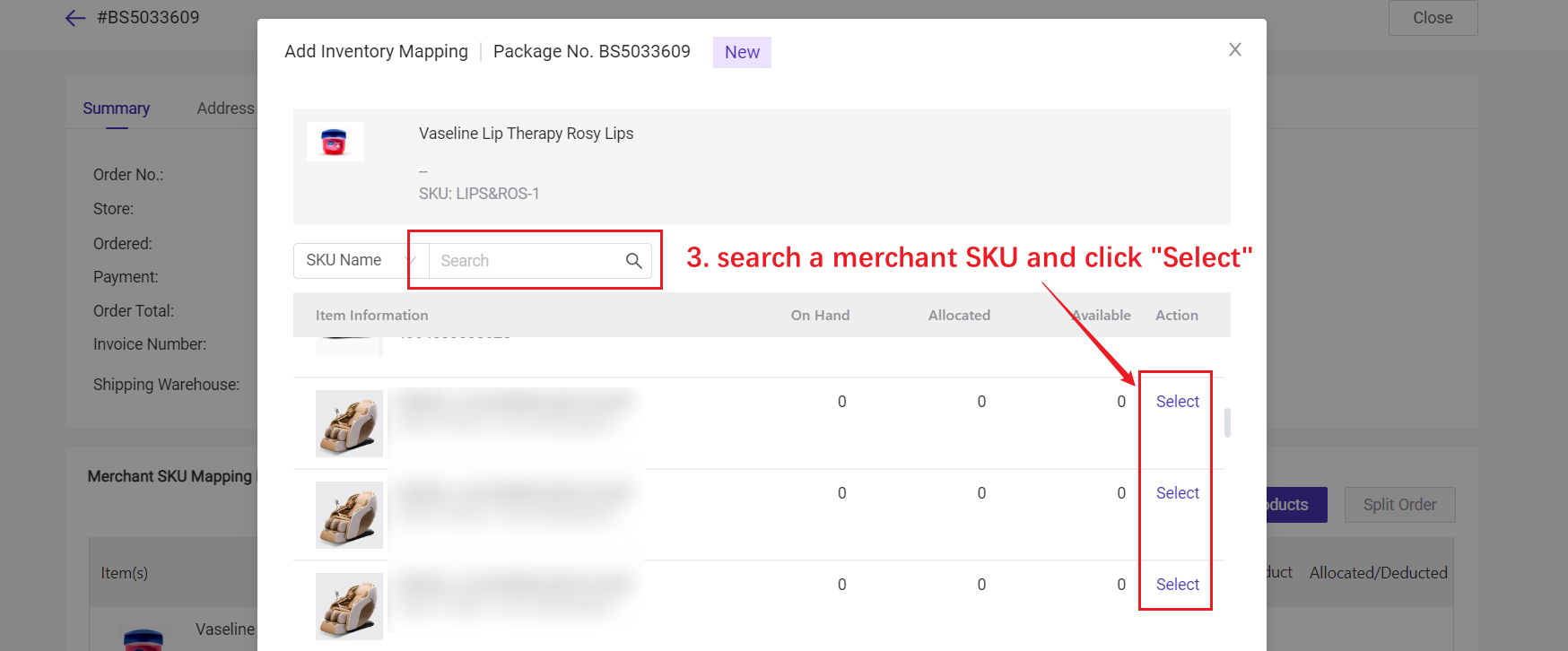

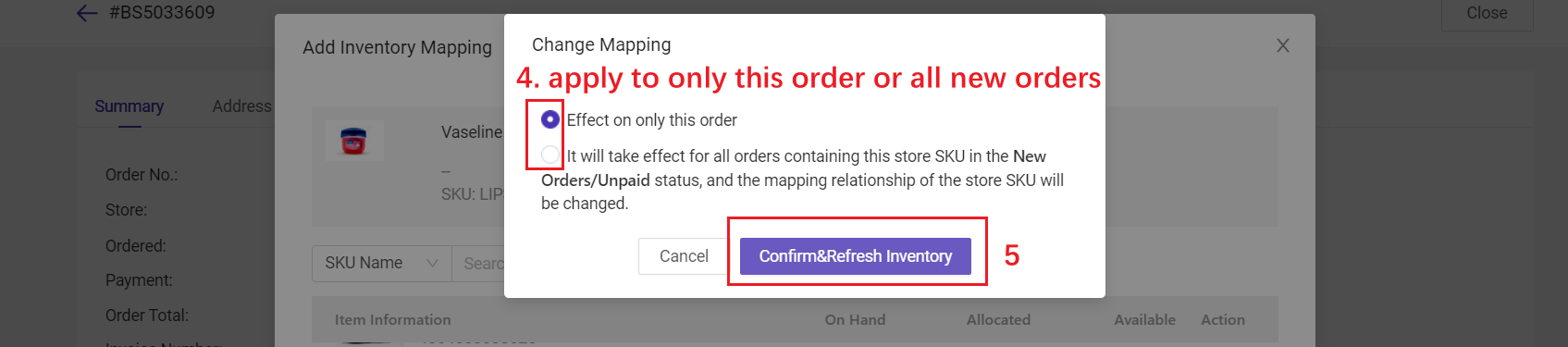

Under the Out Of Stock tab, there are many scenarios. Let's break them down one by one.1) Error: The product of this order doesn't have mapping relations with the Merchant SKU, please set it on the order details page then process the order again

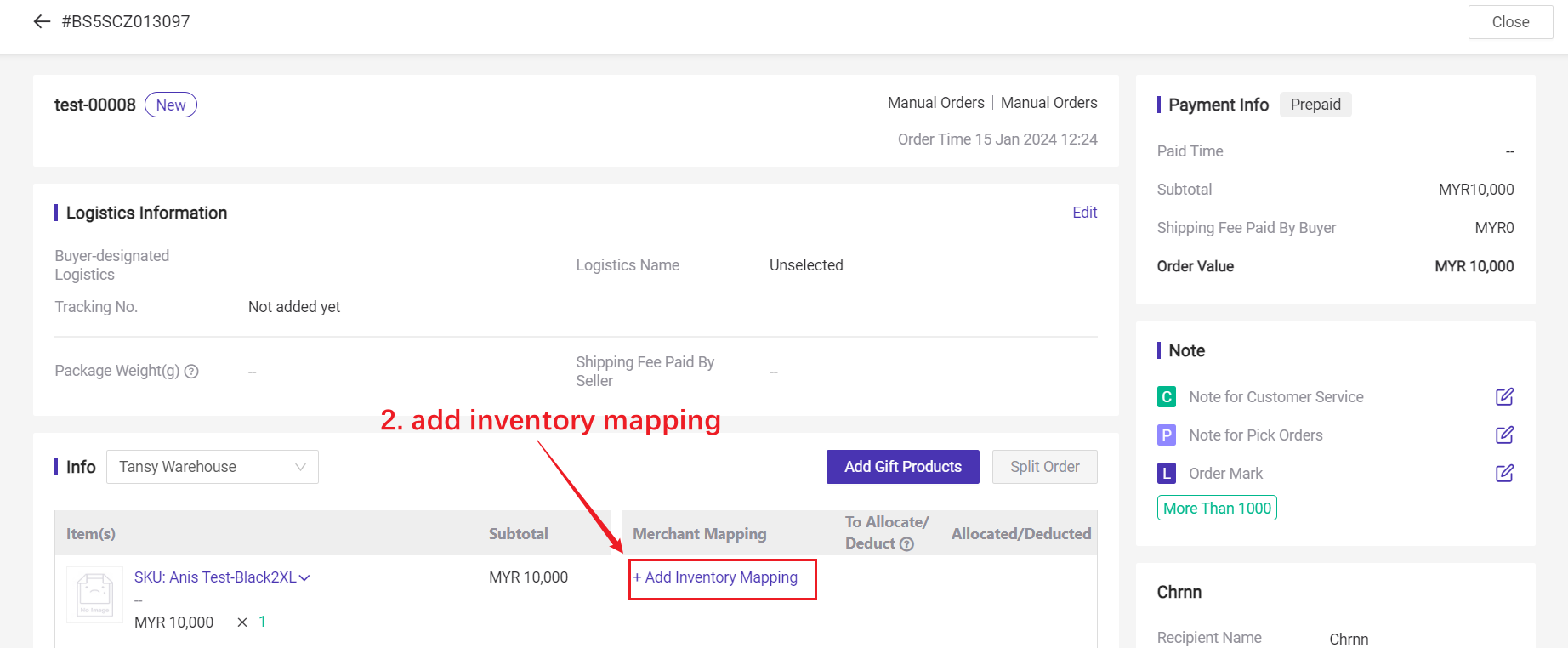

💡Solution: This error means the products in this order don't have mapping relationships with Merchant SKUs on Bigsller. Please first map your store products with Bigseller Merchant SKUs.

You can directly set the mapping relationships on the Order Details page or go to Inventory > the Merchant SKU list.

2) Error: XXX has no stock in the warehouse

💡Solution: The inventory of this Merchant SKU in the warehouse is insufficient. You can click "Out-of-Stocks Statistics" to calculate the required quantity, and add stock by manual stock in/ purchase/ transfer.

🔖 Notes:

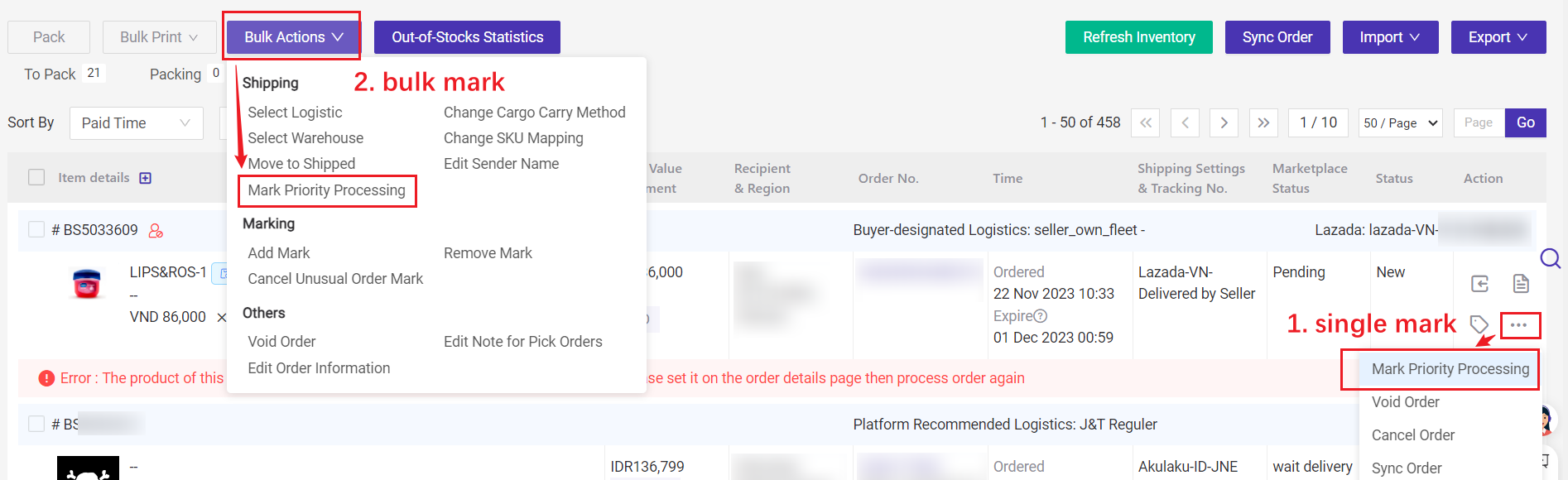

- After you have added the stocks of the merchant SKU, the inventory will be auto refreshed. The system will move the order to “To Pack” list based on the ordered time.

- Orders placed earlier will be prioritized for processing. If you need to set your own priority for processing orders, you can give them a priority processing mark.

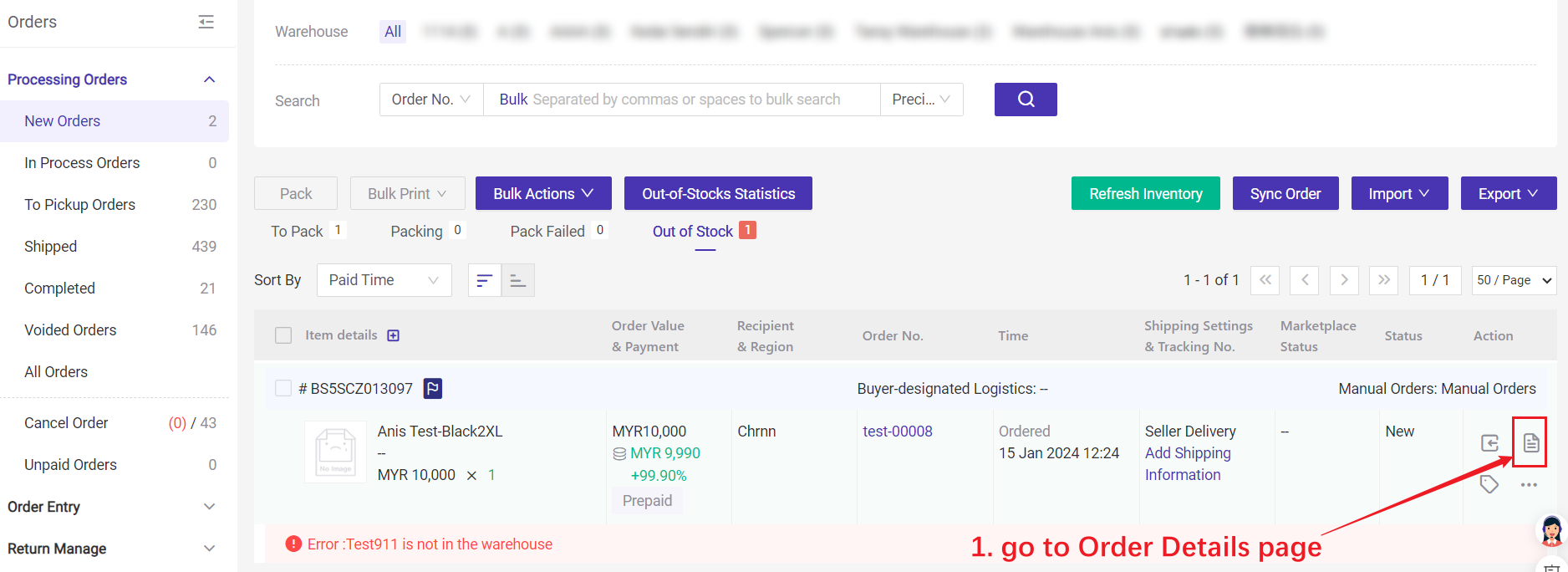

3) Error: XXX is not in the warehouse

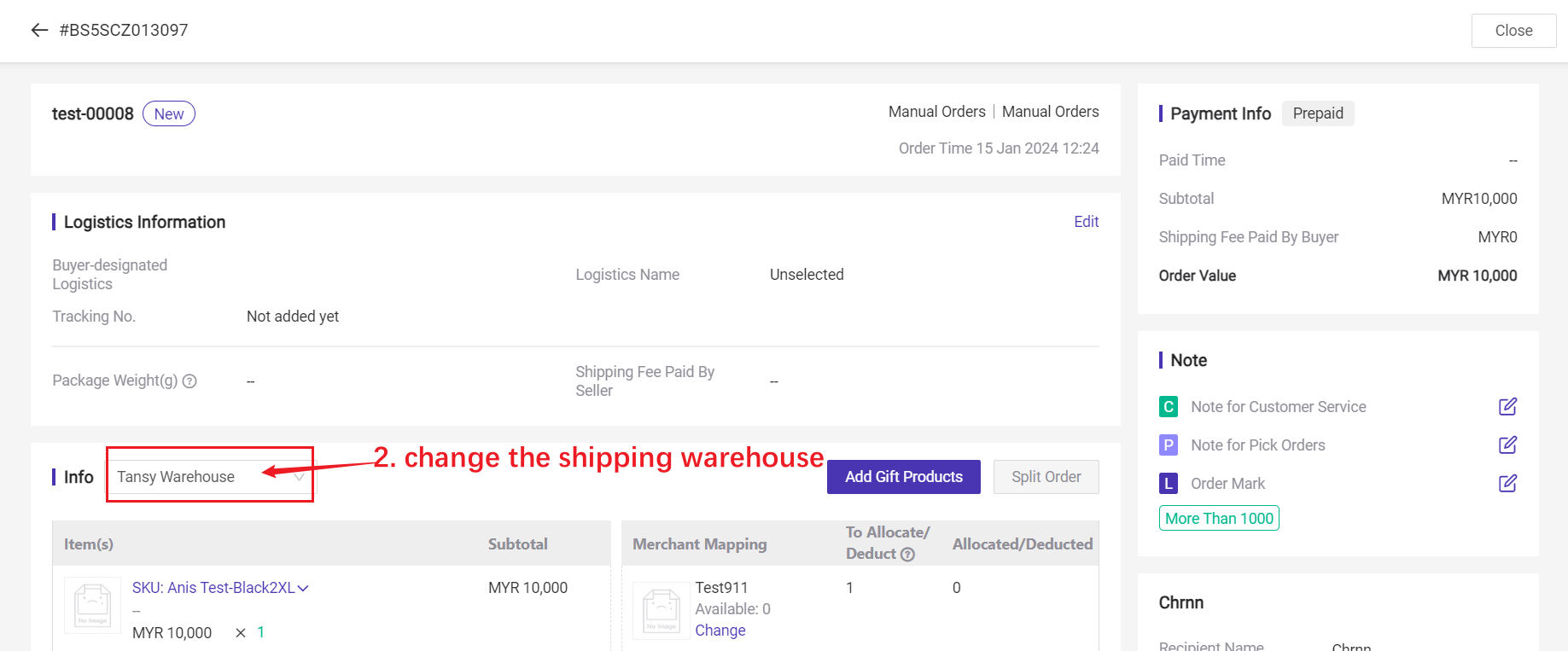

💡Solution: This merchant SKU is not in the selected shipping warehouse, please go to the Order Details page to change the shipping warehouse or add this Merchant SKU to the selected shipping warehouse.

Directly modify the shipping warehouse

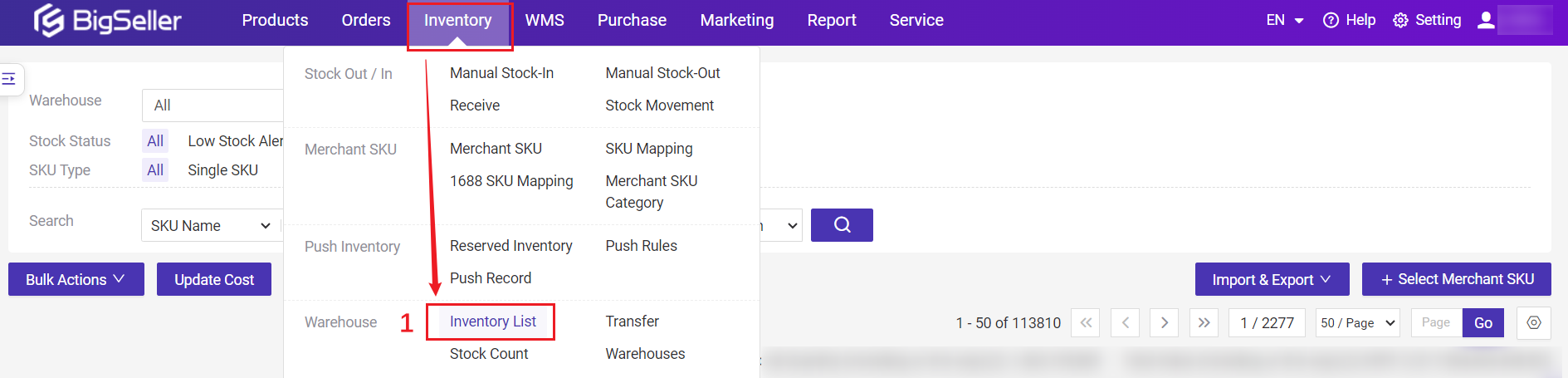

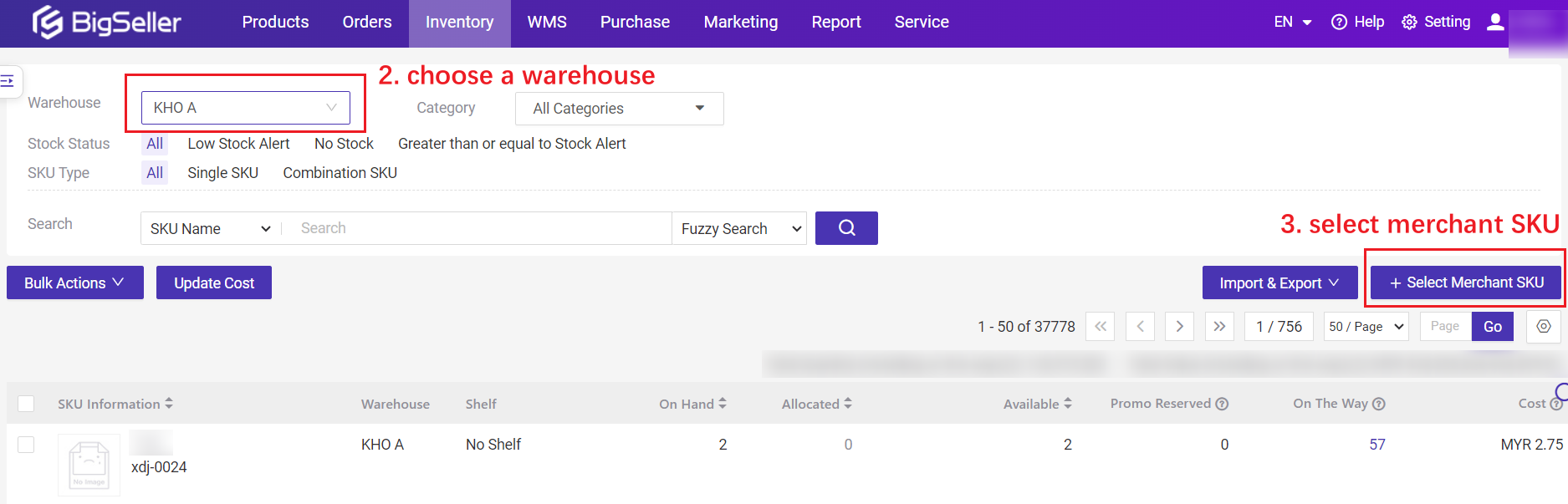

Add the Merchant SKU to the selected warehouse

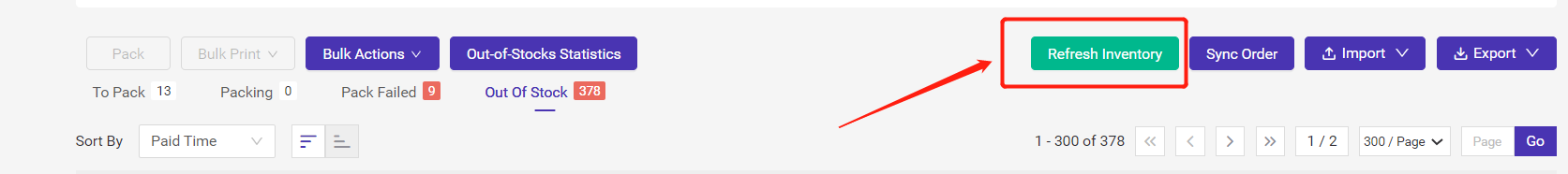

Finally, after you've resolved the above issues, you need to go back to the Out Of Stock tab, click the Refresh Inventory button then the system will check the stock again. If there is enough stock for that order, it will move to the To Pack tab and then you can click Pack to arrange the order.

💡 Note